石油燃气长输管线综合监测系统解决方案

2024.11.18 42592 返回列表

方案介绍:

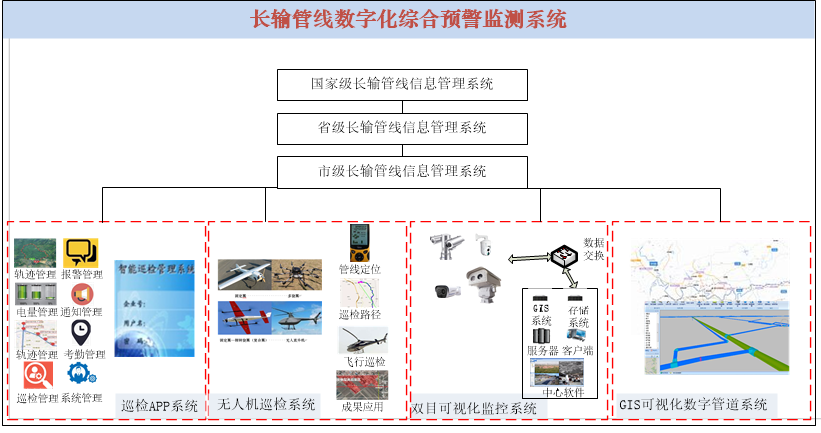

通过采用智能无人机智能巡线方法,结合人工巡线方式,能够最大程度的减少人力损耗,并能够对高后果区实现远程智能、高效、科学化和可视化监测。

通过部署配置人工巡检APP软件,实现对人工的巡检路线记录,考勤打卡,隐患上报,图片视频上报,坐标定位等功能。

利用高清智能可见光加热成像双目双模式视频监控设备,实现对管道路线的可视化视频监控管理,先进的热成像视频监控技术,能够透雾、透霾、抗复杂环境等优势,真正实现可视化全天候的视频监控监测。

搭建多维的GIS地理信息长输管道信息管理系统,对长输管线进行可视化、立体化、多维度、多方式的信息系统管理,将管线自身的相关数据信息、转折点、场站、节点等数据信息进行立体化、实时化的图形展示。

系统设计

方案优势:

1. 智能巡检APP:一键上传、实时定位、考勤管理、轨迹回放、区域管理、电量管理、音视频报警。

2. 无人机智能巡检系统,实现高效化的管线巡检巡护,自动巡航路径飞行,高清画面展示,语音宣传喊话,多样化的成果应用。

3. 热成像加可见光双模式监控,温度成像,透雾透霾,抗复杂天气环境;自主开发的热成像采集模块;灵活先进的云台扫描技术;先进的定位技术;

4. 实现三维一体化GIS显示,数字管道信息展示,立体化、可视化、智能化的管道数据汇总呈现,亲切化的用户界面,实时、动态展示管道信息。

5. web端声音报警、APP、微信公众号、短信等多种报警通知。

6. 可视化数据展示,以折线图、柱状图、雷达图、热力图等形式进行可视化大数据展示。

7. 监控平台系统兼容性强、支持多策略巡航、多报警策略、区域屏蔽、热源管理。

上一篇: 没有了!

下一篇: 危化品园区监管平台

青岛浩海网络科技股份有限公司

股票代码:430695

- 0532-87920299

- 0532-87920299

- haohai@ehaohai.com

- www.ehaohai.com

- 经营地址:青岛市市北区人工智能产业集聚区4号楼

技术支持: 青岛网站建设